In the world of manufacturing, plastic injection molding machines play a crucial role in producing high-quality plastic products. These machines offer automation, precision, and efficiency, making them an indispensable tool for various industries. Plastic injection molding machines are advanced manufacturing tools that facilitate the production of plastic products with exceptional precision and speed. These machines are designed to inject molten plastic into a mold cavity, allowing for the creation of a wide range of plastic components. By utilizing automation and microprocessor control, these machines offer unparalleled efficiency and consistency in the manufacturing process. In this article, we will explore the features and benefits of plastic injection molding machines, highlighting their significance in modern manufacturing processes.

Understanding Plastic Injection Molding

Plastic injection molding is a manufacturing process wherein molten plastic material is injected into a mold under high pressure. The molten plastic cools and solidifies within the mold, taking its desired shape. This process enables the production of complex and intricately designed plastic parts in large volumes.

Benefits of Automation in Plastic Injection Molding

Automation has revolutionized the manufacturing industry, and plastic injection molding is no exception. By integrating automation into the molding process, manufacturers can achieve higher production rates, reduced labour costs, and enhanced product quality. Automation eliminates human errors and ensures consistent results, making it a valuable asset in the production line.

Exploring Automatic Microprocessor Controlled Machines

Automatic microprocessor controlled plastic injection molding machines are at the forefront of modern manufacturing. These machines utilize advanced control systems that precisely monitor and adjust various parameters during the injection molding process. By maintaining optimal conditions, such as injection speed, pressure, and temperature, these machines ensure superior product quality and dimensional accuracy.

Key Specifications of PET Injection Molding Machines

PET injection molding machines are specifically designed for molding products using Polyethylene Terephthalate (PET), a thermoplastic polymer known for its durability and clarity. These machines offer a clamping force ranging from 80 to 250 tons, ensuring the ability to mold products of various sizes and complexities. The automatic microprocessor control system allows for precise control over injection speed and pressure, ensuring consistent results.

Machine Structure: Horizontal PET Injection Molding Machine

Horizontal PET injection molding machines are widely used in the industry due to their ergonomic design and ease of operation. The horizontal structure allows for efficient loading and unloading of molds, maximizing productivity. These machines are equipped with advanced hydraulic systems and servo motors, providing smooth and accurate movements during the molding process.

Customization Services for Tailored Solutions

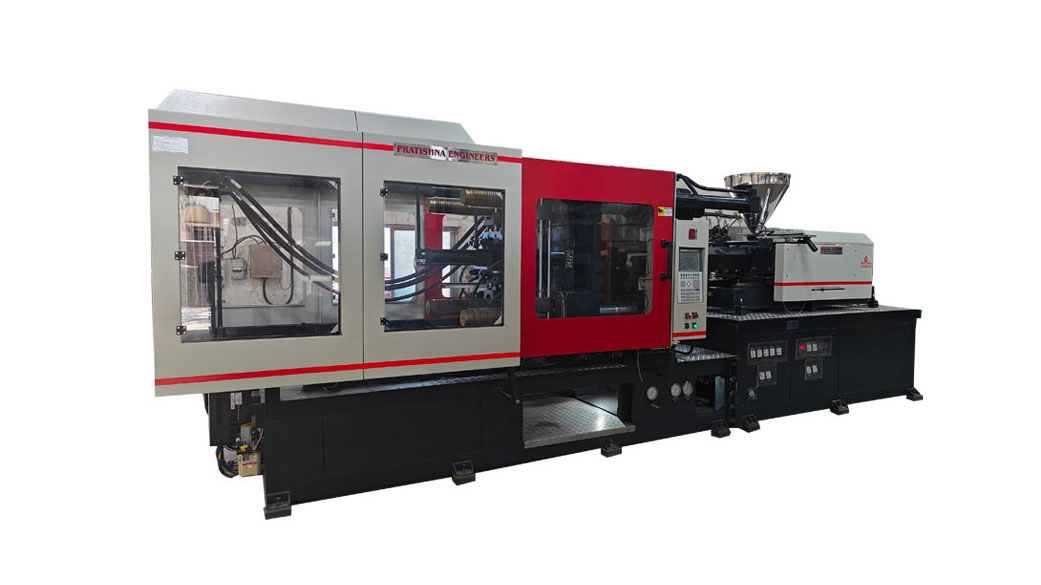

Pratishna Engineers understand the diverse needs of clients. That’s why we offer customization services for plastic injection molding machines. Our team of experts collaborates closely with customers to design and develop machines that meet their specific requirements. Whether it’s modifying the machine’s specifications or incorporating unique features, we strive to deliver tailored solutions for optimized performance.

Plastic Injection Molding Machine Manufacturers in India

India is a hub for manufacturing excellence, and the plastic injection molding industry is no exception. Pratishna Engineers specialize in producing high-quality plastic injection molding machines. We prioritize product reliability, precision, and customer satisfaction, making them the go-to choice for businesses worldwide.

Global Reach: Affordable Products with Timely Delivery

The global market demands efficient and cost-effective solutions. Pratishna Engineers understand this requirement and offer the products worldwide. With streamlined production processes and reliable logistics, we ensure that customers receive their machines within the specified timeframe. Moreover, competitive pricing makes us an attractive option for businesses of all sizes.

Injection Speed and Pressure Control for Optimum Results

Injection speed and pressure are critical factors in the plastic injection molding process. Automatic microprocessor controlled machines excel in this aspect, allowing precise control over injection parameters. By adjusting the injection speed and pressure, manufacturers can achieve optimal flow characteristics, minimize part defects, and enhance the overall quality of the final product.

Low-Pressure Molding Facility for Delicate Applications

Certain applications require a gentle approach due to the delicacy of the components involved. Low-pressure molding is an ideal solution for such scenarios. Plastic injection molding machines equipped with low-pressure molding facilities enable the production of fragile parts without compromising their structural integrity. This process minimizes the risk of damage and ensures the longevity of the finished products.

The Role of Microprocessor Control Panel Board

The microprocessor control panel board is the central control unit of modern plastic injection molding machines. It allows operators to monitor and adjust various parameters with ease. The intuitive interface provides real-time feedback on process variables, enabling operators to make informed decisions for optimal performance. The microprocessor control panel board enhances the overall user experience and ensures smooth operation throughout the production cycle.

Conclusion

Plastic injection molding machines have revolutionized the manufacturing industry by offering automation, precision, and efficiency. These machines enable the production of high-quality plastic products with consistent results. From automatic microprocessor controlled machines to customization services, Pratishna Engineers strive to meet the diverse needs of our clients. With continuous advancements and innovation, plastic injection molding machines are set to play a vital role in shaping the future of manufacturing.