Two-platen injection molding machines are at the forefront of innovation in the manufacturing sector, offering exceptional solutions for large-scale projects. From automotive components to industrial housings, these machines are redefining how large and complex plastic parts are molded. With superior clamping forces, space efficiency, and advanced precision, two-platen injection molding machines have become indispensable for high-volume production. This article delves into their key applications, benefits, and why they are the go-to choice for large-scale manufacturing projects.

Understanding Two-Platen Injection Moulding Machines

Two-platen injection molding machines utilize a unique design comprising a fixed and movable platen, eliminating the need for a third platen. This design significantly reduces the machine’s footprint while enhancing its ability to handle larger molds and deliver precise molding solutions.

Key Features

- Space-Efficient Design: Compact layout ideal for factories with limited floor space.

- High Clamping Force: Provides the strength required for large and thick parts.

- Improved Accessibility: Easier mold changes and maintenance due to open access to the mold cavity.

- Energy Efficiency: Equipped with servo-motor technology for reduced power consumption.

- Precision Molding: Ensures tight tolerances and dimensional accuracy.

Applications of Two-Platen Injection Moulding Machines

Two-platen machines excel in various industries requiring the production of large, intricate plastic components. Below are the most common applications:

- Automotive Industry

Two-platen machines are widely used to manufacture large automotive parts due to their ability to handle complex molds with precision and consistency. Key components include:

- Bumpers

- Dashboards

- Fenders

- Door panels

- Engine covers

- Industrial Equipment Housing

These machines are ideal for producing enclosures for machinery and control panels. The robust clamping system ensures uniformity and stability in these large parts.

- Household Appliances

Large components for appliances such as refrigerators, washing machines, and dishwashers are molded using two-platen machines. These parts demand high dimensional accuracy and consistent quality.

- Construction Sector

Plastic panels for building facades, window frames, and structural supports are effectively manufactured using two-platen machines, thanks to their ability to handle large molds.

- Logistics and Storage

Two-platen machines are extensively used to produce large bins, pallets, and crates. These products require durability and precision to withstand rigorous use.

- Medical Equipment Enclosures

Large plastic casings for medical devices like MRI machines and CT scanners are another key application. The clean and precise operation of two-platen machines makes them suitable for medical-grade production.

Benefits of Two-Platen Injection Moulding Machines

- Large Mold Capacity

Two-platen machines are designed to accommodate large and complex molds, making them ideal for producing sizeable plastic parts with intricate designs.

- High Clamping Force

The robust clamping system ensures that the molds remain securely closed during the injection process, enabling the production of thick and heavy parts.

- Space Efficiency

Compared to three-platen machines, two-platen machines have a smaller footprint, saving valuable factory space.

- Enhanced Accessibility

The open design allows for easier mold changes and maintenance, improving operational efficiency.

- Precision and Consistency

Servo-driven systems and advanced controls ensure high precision, tight tolerances, and repeatable results.

- Energy Savings

Servo-motor technology reduces energy consumption, leading to significant cost savings over time.

Popular Two-Platen Injection Molding Machines

DYOTA Series

The DYOTA Series features a space-saving two-platen design with advanced servo-technology, ensuring high performance and energy efficiency.

Key Highlights:

- Flexible Clamping System: Modular design with independent clamping cylinders for even force distribution.

- Quick Mold Changes: Allows for side mold changes, particularly useful in factories with height limitations.

- Energy Efficiency: Servo-driven pumps and continuous oil filtration reduce energy and maintenance costs.

DKM-TP Series

Renowned for its precision and reliability, the DKM-TP Series is suitable for automotive, packaging, and industrial applications.

Key Features:

- Clamping Force: 600 to 4,000 tons.

- Advanced Control System: Enables real-time monitoring and process optimization.

- Safety Features: Includes interlocks, emergency stop buttons, and fault detection systems.

Challenges of Two-Platen Injection Moulding Machines

- Initial Investment

The upfront cost of two-platen machines is higher than traditional three-platen systems. However, the long-term savings in energy and maintenance often offset this expense.

- Complexity of Operation

Due to their advanced technology, these machines may require skilled operators and additional training for optimal use.

Future of Two-Platen Injection Moulding Machines

- Industry 4.0 Integration

Smart technologies like IoT and AI are increasingly being incorporated, enabling predictive maintenance and real-time analytics.

- Advanced Materials

Two-platen machines are being adapted to handle innovative materials like bioplastics, supporting sustainability initiatives.

- Modular Designs

Future designs will focus on modularity, allowing manufacturers to easily upgrade or scale their operations.

Why Choose Two-Platen Injection Moulding Machines?

Two-platen injection molding machines are transforming large-scale manufacturing with their space efficiency, precision, and energy-saving capabilities. From automotive to medical and logistics, these machines offer unparalleled benefits for producing high-quality, large-scale plastic components.

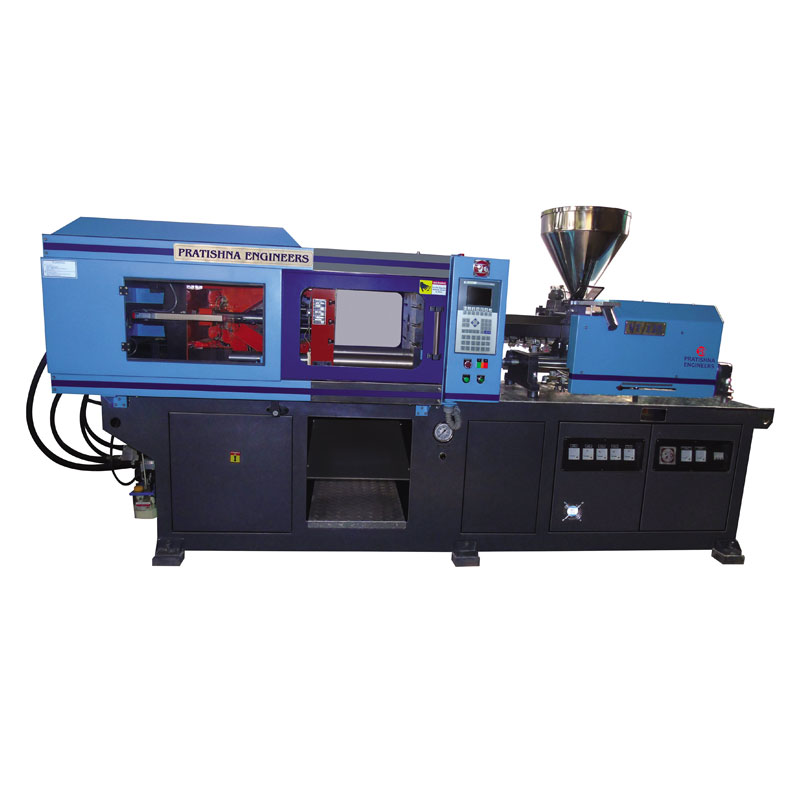

Explore a wide range of advanced two-platen injection molding machines at Pratishna Engineers and Pratishna Machines. Invest in cutting-edge technology to elevate your production capabilities today.