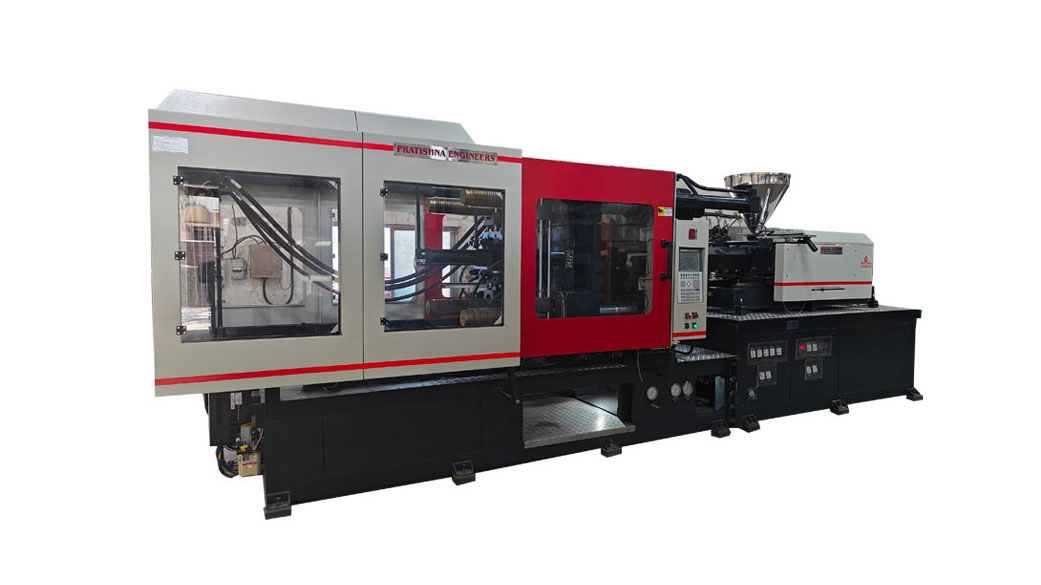

Manufacturer of Injection Moulding Machine, Principle of Injection Moulding Machine, Injection Moulding Machine Supplier, Injection Moulding Machine Manufacturers in India

Pratishna Engineers Ltd. is a leading company for top-of-the-line Injection Moulding Machines for electric & electronics components. With our cutting-edge technology and unwavering commitment to quality, we have established ourselves as a leading manufacturer and exporter in the industry. Our state-of-the-art machines are designed to meet the diverse needs of the Electric & electronics market, providing efficient and precise production solutions that deliver exceptional results.

At Pratishna Engineers Ltd., we understand the importance of producing high-quality Electric & electronics components that meet both functionality and aesthetic standards. Our Injection Moulding Machines are equipped with advanced features and robust construction, ensuring reliable and consistent performance. With customizable options, our machines can cater to various product sizes, designs, and materials, giving you the flexibility to create a wide range of electric & electronics products.

With our expertise and extensive skill in the industry, we take pride in delivering reliable and efficient Injection Moulding Machines that empower your production processes. Our dedicated team of professionals works closely with you to understand your specific requirements and provide tailored solutions that meet your needs and exceed your expectations. When you choose Pratishna Engineers Ltd., you can be confident in the quality, durability, and precision of our machines, making them the perfect investment for your electric & electronics products manufacturing business.

What is an Injection Moulding Machine for Electric & electronics components?

An Injection Moulding Machine for Electric & electronics is a specialized piece of equipment used in the manufacturing process of various electric & electronics components. Injection Moulding Machine plays a crucial role in transforming raw materials into the desired shape and form of electric & electronics components.

The injection moulding procedure involves heating the plastic material until it becomes molten and then injecting it into a mould cavity. The mould is specifically designed to create the desired shape of the item. Once the molten plastic cools and solidifies inside the mould, the machine opens the mould, allowing the freshly formed item to be ejected.

Injection Moulding Machines are designed with precision and efficiency in mind, ensuring consistent production of high-quality electric & electronics components. They offer features such as temperature control, pressure regulation, and automated processes to achieve precise moulding and reduce production time.

Injection Moulding Machines for Electric & Electronics are vital for manufacturers in the industry, as they provide a cost-effective and efficient solution for producing large quantities of products with consistent quality and accuracy. With advancements in technology, these machines continue to evolve, offering increased speed, energy efficiency, and versatility, making them indispensable tools for the electric & electronics manufacturing sector.

Types of Electric & electronics components Manufactured Using Injection Moulding Machine

Injection moulding machines are widely used in the manufacturing of several electric and electronics components. Here are some examples of the types of components that can be manufactured using an injection moulding machine:

- USB Cable: The machines are commonly utilized to manufacture USB cables used for data transfer and charging in electronic devices. Injection moulding machines ensure the production of cables with proper insulation, durability, and reliable connection interfaces.

- Switches: They are employed to produce switches used in various electronic devices and appliances. These switches can include toggle switches, push-button switches, rocker switches, and slide switches, ensuring reliable and convenient control mechanisms.

- Extension Cables: Moulding machines play a vital role in the manufacturing of extension cables used to extend the reach of power or data connections. Injection moulding machines enable the fabrication of extension cables with proper insulation, connectors, and durability for safe and reliable use.

- VGA Cable: The machines are commonly used to manufacture VGA cables used for video display connections in computers and other electronic devices. Injection moulding machines ensure the manufacture of cables with proper shielding, precise connector fittings, and reliable signal transmission.

- PCB/PCBA Casing for Circuit Board Housing Molding: Injection moulding machines are utilized in the production of casings for PCB (Printed Circuit Board) and PCBA (Printed Circuit Board Assembly) components. These casings deliver protection, structural support, and electrical insulation for the circuit boards, ensuring proper functionality and longevity.

- Spare Machine Parts: They are commonly employed to produce spare parts for electronic devices and machines. These parts can include housings, connectors, brackets, and other components that require precise dimensions and materials to ensure proper fit and functionality.

- ARM Chipset: The machines play a crucial role in the manufacturing of ARM (Advanced RISC Machines) chipsets used in various electronic devices. Injection moulding machines enable the production of chipsets with intricate designs, precise connections, and optimal performance characteristics.

- Dual Power Connectors: Injection moulding machines are extensively used to fabricate dual power connectors used in electronic devices and power supply systems. These connectors enable the simultaneous connection of multiple power sources or devices, ensuring efficient power distribution and safe operation.

Injection moulding machines deliver the precision, flexibility, and efficiency required to manufacture a wide range of electric and electronics components. The capacity to produce complex shapes, reliable connections, and consistent quality makes these machines essential in the electric and electronics industry.

Why Choose Us?

Pratishna Engineers Ltd. stands out as the leading injection moulding machine manufacturers in India. Our primary focus is on ensuring the satisfaction and happiness of our buyers, as we believe that it brings manifold benefits to any company. We have streamlined the payment process, offering convenient options both offline and online. With a strong commitment to essential business values such as integrity, trustworthiness, and loyalty, we treat each customer and employee with utmost respect. Our machines are designed to cater to the diverse preferences of consumers across various market segments, showcasing exceptional performance and capability. If you are seeking a distributorship opportunity for injection molding machines with a renowned and reliable company, Pratishna Engineers Ltd., please feel free to contact us